The Importance of Transformer Oil in Performance

Transformer oil analysis plays a critical role in maintaining the efficiency of electrical equipment. Mineral oil is the most widely used transformer oil due to its excellent insulating and cooling properties. It transfers heat to the transformer housing through convection, ensuring smooth operation and preventing overheating. By filling internal spaces effectively, mineral oil boosts performance and prolongs the transformer’s lifespan. Oil-filled transformers benefit from better heat dissipation and reliable operation. Regular oil testing preserves these advantages. Technicians perform transformer oil analysis to gather essential insights about the transformer’s internal condition. Routine sampling and testing protect oil quality, ensuring long-term efficiency and reliability.

Detecting Issues Through Advanced Oil Analysis

Dissolved degradation and decomposition products in transformer oil signal weak points within the system. These by-products indicate wear, internal damage, or faults. Standard oil quality checks often miss these issues, so advanced methods become essential. Gas-in-Oil Analysis plays a crucial role in identifying these problems. This testing method tracks the oil’s aging process and highlights potential issues early. Laboratory analysis breaks the oil into its smallest components, providing insights similar to a blood test in human health. These results allow technicians to detect contamination or early signs of wear.

Standards and Proper Procedures for Accurate Testing

The DIN EN 60422 standard outlines proper guidelines for transformer oil analysis. Following these guidelines ensures accurate and consistent results. Correct sampling techniques prevent contamination and protect the validity of the analysis. Adhering to these procedures helps uncover potential issues early. Regular testing improves transformer reliability, protects system performance, and ensures that transformers operate efficiently throughout their lifespan.

Water in Oil sensor | ST-100 Transmitter

The ST-100 water in oil sensor delivers fast, reliable, and precise readings. It serves as an ideal choice for real-time monitoring of oil moisture. The sensor continuously tracks both water activity and temperature in oil. A clear display shows these values, so users can quickly see either absolute ppm or relative water activity (aw-value) for oil moisture. This design enables accurate, consistent data for managing oil quality.

The ST-100 works well for transformer oil, lubricating systems, and hydraulic oils. Its compatibility with lubricating, hydraulic, and insulating oils ensures long-term performance. It supports preventive maintenance, reduces equipment downtime, and extends oil lifespan. Integrated directly into the oil circuit, the sensor delivers real-time data, so users can respond immediately to any rise in water content. This setup lowers the risk of unnoticed moisture spikes.

Built for durability, the ST-100 functions as a dependable moisture in oil transmitter. It provides lasting performance across many industrial applications. This ST-100 Transmitter also helps optimize equipment health and prevent transformer failures. The ST-100 serves as a cost-effective, high-performance solution. It integrates easily into OEM systems, providing reliable data on oil moisture content and supporting a wide range of essential uses.

We offer you advice on the topics of: Temperature and Humidity | Moisture Content Oil | Water Activity

Moisture measurement in oil | ST-200 Sensor

The ST-200 Moisture measurement in oil Sensor is a high-precision tool for measuring moisture in oil online. It uses WGM Support technology, giving it exceptional sensitivity to changes in water content. This allows accurate, real-time monitoring of oil quality, which is essential for reliable equipment performance.

The sensor is highly sensitive to water contamination. It can detect dissolved, free, and emulsified water. Its wide test range of up to 1015 allows accurate readings in varied conditions. Unique grounding technology enhances reliability and durability, while the sensor’s advanced design makes cleaning easy.

The ST-200 meets international standards and is suited for commercial and industrial environments. It provides continuous, 24/7 oil quality monitoring to keep essential equipment safe. By enabling preventive maintenance, it helps avoid costly downtime and reduces expenses due to oil quality issues. Additionally, it lowers oil change and disposal costs, promoting environmentally friendly operations.

The Moisture measurement in oil is widely used in industries such as oil production, refineries, power plants, power transmission, construction machinery, aviation, transportation, steel and metallurgy, oil storage, and manufacturing. It works with many types of oil, including lubricants, hydraulic oils, gear oils, engine oils, fuel oils, insulating oils, turbine oils, and both light and heavy oils.

The ST-200 pairs easily with the ST-200 indicator meter for precise monitoring of moisture and temperature. Warning points are flexible, and the built-in AC/DC module provides a stable 24V DC power supply. Together, these features form a complete solution for maintaining and monitoring oil quality in various industrial applications.

We would be happy to advise you on the following topics: Moisture Sensor | oil quality sensor | oil moisture and water activity.

Gas in Oil Analysis | TOGA-100-GC | Dissolved gas analysis (DGA)

Gas-in-Oil-Analysis | TOGA-100-GC

DGA analysis (Dissolved Gas Analysis) remains a top method for DGA diagnosis in transformers and tap changers. This gas in oil analysis allows early fault detection and plays a key role in DGA condition assessment. As transformers insulating oil and insulation materials age, gases in oils dissolve, especially during thermal or electrical faults. Through oil sample analysis, operators can detect early signs of fault development.

Technicians use DGA dissolved gases as indicators to monitor trends over time. They identify unique gas patterns tied to specific faults. Dissolved Gas in Oil Measurement gives crucial insights into the transformer’s condition. The TOGA 100-GC system supports total gas content measurement for mobile, on-site DGA. It delivers quick, accurate results, identifying gaseous decomposition products linked to fault types. The TOGA 100-GC separates all eleven gas components in a single injection, using the ASTM 3612C standard for dissolved gas analysis with headspace injection.

The M-Labor series gas chromatograph supports analysis of dissolved gases in laboratories with an optional automatic sampler. For field applications, the TOGA 100 Portable enables efficient DGA analysis with a small helium tank, making on-site dissolved gas analysers readily available. Each TOGA 100 GC’s column oven offers high sample throughput, with fast heating and cooling to meet heavy analysis demands.

TOGA GC systems are compact, lightweight, and modular. Their design supports easy upgrades and maintenance. These systems apply the ASTM D3612C method for analysis of dissolved gases. Their accuracy and efficiency in DGA diagnosis make them ideal for transformer health monitoring, setting the standard in oil sample analysis and DGA condition assessment.

We offer you advice on the topics: Gas in Oil Analysis | Dissolved Gas Analysis DGA | Transformer oil analysis

Breakdown Analyzer | ÖLPG | Oil Tester

The ÖLPG Oil Tester is a portable “Breakdown Analyzer” designed for on-site oil testing. This device fully automates the breakdown voltage or dielectric strength test for insulating oil, making the process both fast and cost-effective. A critical test for transformer oil quality is the breakdown voltage test: lower resulting voltage indicates lower oil quality. Ultra-light transformer oil testers like the ÖLPG are powerful and ideal for on-site testing, enabling operators to assess insulating oil quality directly, without sending samples to a lab. Immediate action can be taken based on results if necessary.

A quick procedure and shutdown time of less than five µs enable efficient testing. High-contrast display facilitates handling and navigation, while the Breakdown Analyzer also supports non-destructive testing of synthetic, ester, and silicone oils. Breakdown voltage in insulating oils is determined easily by sampling oil directly from the transformer or current transformer, then subjecting it to the fully automated test. Results provide operators with a clear assessment of oil quality, guiding decisions on retention or replacement.

Automatically generated test reports are ready for download as PDFs onto a USB stick. Rapid voltage cut-off ensures safe, non-destructive testing for synthetic, ester, and silicone oils. Pre-defined, fully automated test sequences adhere to current international standards, guaranteeing compliance with legal testing requirements. In conclusion, the ÖLPG Oil Tester represents a significant advancement in oil testing technology. Offering a reliable and efficient solution for operators in need of accurate and timely results.

We offer you advice on the topics of: Dielectric breakdown voltage | dielectric strength | oil tester

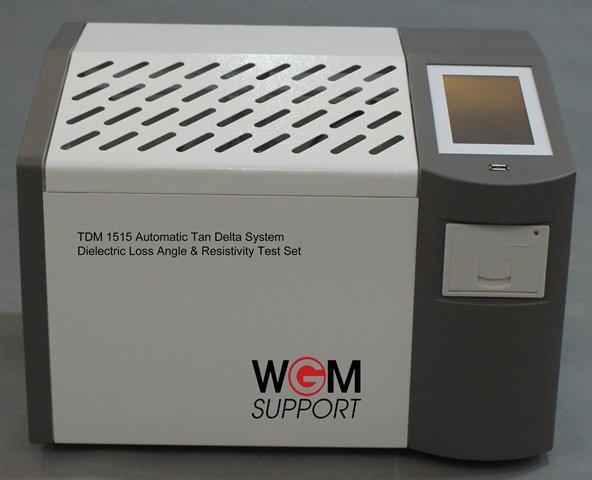

Tan Delta Meter | TDM 1515 | Tan Delta Measurement

Tan Delta Meter | Tan Delta Measurement

The Tan Delta Meter TDM1515 delivers accurate dissipation factor measurement of insulating oils. It measures the dielectric dissipation factor in transformer oil, insulating fluids, and other materials. The device supports advanced dielectric analysis, enabling users to evaluate tan delta resistivity, specific resistance oil, and capacitance. These measurements provide clear insights into fluid losses and help assess the condition of the insulation.

The TDM1515 serves as a versatile Tan Delta Analyser for Oil. It includes an integrated oil test cell that handles dissipation factor measurement oil without requiring additional components. The Tan Delta Tester Oil features several advanced components, including high-frequency induction heating, a precise temperature sensor, a measuring bridge, and AC and DC power sources. A standard capacitor and digital IC circuits improve performance and measurement reliability.

High-frequency induction heating ensures quick and even warming of the oil test cell. The system allows users to adjust the heating easily for precise control. The built-in drain system simplifies oil removal, making the process safe and efficient during Transformer oil Tan Delta testing.

In AC test mode, the TDM1515 uses the AC-DC-AC conversion method to prevent voltage and frequency instability. It maintains stable operation, even when the voltage generator is active. The integrated SF6 three-pole capacitor shields insulating oil dissipation factor and capacitance measurements from temperature and humidity interference.

The TDM1515 excels in professional Tan Delta Measurement applications. It provides reliable results for transformer oil tester tasks and long-lasting performance, making it an essential tool for professionals in dissipation factor measurement of insulating oils.

We offer you advice on the following topics: TDM1515 | Dielectric Dissipation Factor | Transformer Oil

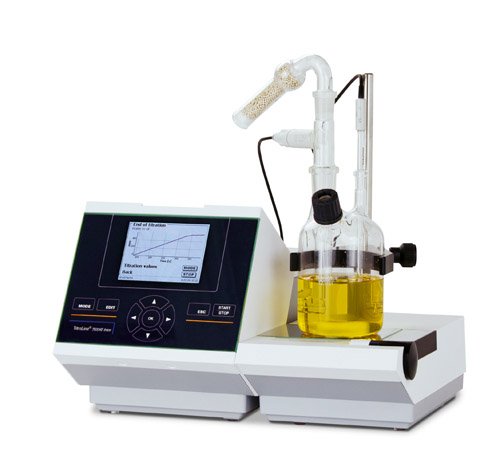

Karl Fischer Water Content | KF-700 | Determination of water content

Karl Fischer Titration KF-700 | Determination of water content – The Karl Fischer Titration method for analytical water determination is considered the most important method for determining water content. Volumetric titration is the “classical” Karl Fischer titration.

The fundamental difference between volumetric and coulometric titration is the method used. One advantage of the volumetric method over the coulometric method is the lower effort required. The Karl Fischer volumetric titrator is more flexible when using solvents. The measuring range goes from 0.01 percent to 100 percent. For water content and water determination, the Karl Fischer method is used in the laboratory.. For all its advantages, manual titration is still established as the standard application in the laboratory. A piston burette with exchangeable dosing attachment is the first choice when perfection and flexibility are required. With regard to the aging process of transformer oil, the Karl Fischer Titration KF-700 is used. A special form of dosing is the “Preparing solutions” mode.

In this mode, a solvent is dosed up to the desired target concentration. A sample is weighed in, the volume added is calculated using a calculation formula and then added. This mode is suitable, for example, for the preparation of standards and solutions for viscometry. Important features: Automatic calculation of the addition volume without additional PC software. Dosing and filling speed can be optimally adapted to the dosing solution. Several methods with different parameters can be stored. Automatic transfer of the weight of a connected balance.

Usually, 10-15 user methods are sufficient for most needs.

We offer you advice on the topics of: Determination of water content | Karl Fischer Titration | Karl Fischer Method

Karl Fischer Water Content Determination | KF-750

Karl Fischer Titration KF-750 | Determination of the water content: Karl Fischer Titration has its place in every laboratory. Karl Fischer Titration KF-750 The KF-750 is a coulometric titrator. The water content and the water content determination according to Karl Fischer Titration impresses with its very good accuracy. With this KF titrator, nothing can actually go wrong when determining the water content according to Karl Fischer. The display, which is large and easy to read, shows every step in the process in a dialog. The pre-parameterized methods thus additionally facilitate the work. In addition, the versatility of the two KF titrators makes the instruments efficient and easy to operate. The KF measuring station is suitable for almost all areas such as the pharmaceutical, chemical, food or petroleum industries.

The coulometric KF titrator is the ideal instrument for determining even the lowest water content in samples. In the coulometry of a titration solution, the determination of the concentration titer is not necessary, making it easier to operate than in volumetric titration. Many experienced analysts still feel the smell of pyridine in their nose with horror when they hear the name Karl Fischer. However, modern reagents and easy-to-operate analytical instruments cleaned up thoroughly with such ideas. Today, coulometric and volumetric Karl Fischer titrators allow practically all applications to be performed simply, quickly and accurately. Because of its selectivity and accuracy, Karl Fischer titration has become the most important method for water and moisture determination. With the KF-750, titration can also be followed “live” in the form of a measurement curve. At the touch of a button, it is possible to switch between classic and graphical display.

We offer you advice on the topics of: Determination of water content | Karl Fischer Titration | Karl Fischer Method

Karl Fischer Water Determination | KF-7751 | Water Content

Karl Fischer Titration KF-7751 | Determination of Water Content – The Karl Fischer Titrator KF-7751 is a generalist when it comes to potentiometric and volumetric titration. As an universal titrator, the KF-7751 offers more application possibilities than the KF-700. In practice, there are differences between coulometric and potentiometric or volumetric titration. After switching on the instrument, the Karl Fischer Titrator starts working immediately, with the default settings starting in the background. The KF titrator has several interfaces for data communication. It is possible to operate an analytical balance via the interface to the KF titrator. To connect a printer, use the USB ports of the device. Karl Fischer titration has also become established for transformer oils for determining the water content in the oil or the water content. The Karl Fischer Titrator can be cleaned with a soft cloth and water using normal household detergent.

General properties: Brilliant TFT display, which can be read even from the side. Exchangeable caps with storage of all relevant cap and reagent data in the cap. Unlimited communication via up to two USB-A, one USB-B, one LAN and two RS232 interfaces. Storage of results as PDF and CSV on USB stick or network.

Preinstalled standard methods. Special features of the KF-7751: Wireless electrode recognition for ID electrodes for highest security during measurement and calibration. High-resolution inputs for pH/mV electrodes and temperature measurements for pH, ISE, redox titrations. Ideal for non-aqueous titrations such as acid and base number in oils. Measuring input for polarizable electrodes. Linear and dynamic titration to inflection points (equivalence points) and titrations to end point. pH Stat titrations. Volumetric KF titration.

We offer you advice on the following topics: Determination of water content | Karl Fischer Titration | Karl Fischer method

Force Tensiometer | Digital Tensiometer

Versatile Functions for Precise Tension Measurements

The Force Tensiometer provides a modern and reliable method for the precise determination of surface wetting. By measuring the tensile force generated when immersing a ring or plate, the device delivers accurate results. Two well-established methods are available for determining surface and interfacial tension between two media: the Du-Noüy ring method and the Wilhelmy plate method.

The digitally controlled Sigma 200 Tensiometer performs these measurements fully automatically. With a single button press, the process starts, ensuring a fast and straightforward operation. This user-friendly design not only saves time but also ensures precise and reproducible results. In addition to tension measurements, the Tensiometer allows for the measurement of liquid density, further enhancing its versatility.

Comfortable Data Collection and Precise Quality Analysis

The Tensiometer operates as a standalone device, equipped with a motorized table that enables highly precise positioning of the sample vessel. During measurement, the Du-Noüy ring immerses in the sample, and the device captures the forces generated. The motorized sample table gradually moves downward, measuring the forces directly on the ring or plate lamella. The integrated display immediately shows the measurement values, enabling quick, straightforward data interpretation.

One particularly valuable feature of the digital Tensiometer is its capability to analyze the interfacial tension between oil and water. The ring method provides early indications of the oil aging process, which plays a key role in quality monitoring. ASTM Standard D971-99 2012 describes and standardizes this method for interfacial tension measurement. This makes the digital Tensiometer an essential instrument for quality control in numerous industries. In the chemical and food industries, it meets the highest standards of accuracy, speed, and efficiency, ensuring continuous quality assurance.

We will be happy to advise you on the following topics: Force Tensiometer | Du-Noüy-Ring | Density.

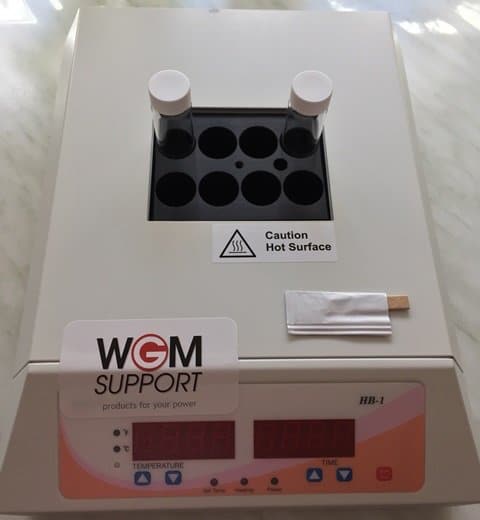

Corrosive Sulphur | CS100 | Corrosive Sulphur Kit

The CS100 Corrosive Sulphur Kit provides a practical and cost-effective alternative to expensive laboratory tests. Its purpose is to detect corrosive copper sulphide deposits accurately. These deposits frequently cause multiple issues, which often lead to transformer failures. Standard inspections rarely reveal these deposits, as technicians must unwind copper wire and de-oil the paper to see the shiny sulphide deposits clearly. Usually, copper wires display dark or multicolored surfaces, and their discoloration can vary greatly along the entire length of the conductor. Until recently, costly laboratory tests were the only reliable method for detecting corrosive sulfur in transformer oil.

Sulfur exists in transformer oil in different forms and various compounds. Copper sulfides can appear with very diverse characteristics. Because of this, technicians suspect that undetected copper sulfides likely cause numerous malfunctions in transformers and reactors. The portable CS100 Kit offers a rapid, convenient, and affordable testing option.

Common copper corrosion tests refer to established procedures, such as ASTM D1275 Method B and IEC 62535 (the CCD test).

The IEC 62535 procedure, known as the CCD test and formerly named Cigre A2.32.TF01, tests copper conductors by accelerated oxidation at high temperatures. During this process, technicians wrap copper conductors in kraft paper and then perform a visual inspection. This step aims to identify corrosive sulfur compounds, which could contaminate the cellulose insulation with copper sulphide.

The ASTM D1275 Method B also uses accelerated oxidation, but on an electrolytic copper strip at 150°C for 48 hours. Afterward, a visual assessment checks for sulfur compounds that might contaminate copper surfaces. This method provides additional insights, allowing for a more comprehensive understanding of copper contamination risks.

We offer you advice on the following topics: Corrosive sulphur | Insulating Oil | Transformer oil

Mobile Particle Counter | PZMG 100

The PZMG100 is a mobile particle counter which can be used to quickly and easily check oil cleanliness and oil condition in hydraulic and lubrication systems during a service call. Samples can be taken directly via a pressure line or via the integrated pump. A measurement can be performed manually or automatically at a predefined time interval. Portable particle counters are preferably used for the on-site analysis of operating oils in hydraulic systems. Precise measurement of particle shapes and particle sizes in different versions. The mobile particle counter cleans the oil and measures its quality. High-quality particle counters from WGM Support for particle measurement during maintenance with the possibility of flow visualization.

We offer you advice on the following topics: Mobile particle counter | Operating oils | Hydraulic oil

PPC Lab Particle Counter – Portable Particle Counter with Lab Quality

This PPC Lab particle counter is suitable for both mobile and stationary use. The measurement results are output in the common purity classes ISO 4406; NAS 1638; SAE AS 4059; GJB 420; GOST 17216. Thanks to the 32-bit high-performance control unit, flexible measurements and simultaneous data storage of different measuring points are possible. The integrated printer outputs the measurement results on paper directly on site. The dialog-oriented setting menu of the PPC Lab allows the display in different languages (German, English, French, Spanish, Portuguese, Russian, Dutch, Chinese and Finnish). PPC Lab’s modern, technically advanced components, including the volumetric sensor measuring cell, provide high resolution and measuring accuracy. All particles are detected, counted and measured by the sensor. Up to 32 freely selectable size channels display the particle number and particle size distribution.