The CS100 Corrosive Sulphur Kit provides a practical and cost-effective alternative to expensive laboratory tests. Its purpose is to detect corrosive copper sulphide deposits accurately. These deposits frequently cause multiple issues, which often lead to transformer failures. Standard inspections rarely reveal these deposits, as technicians must unwind copper wire and de-oil the paper to see the shiny sulphide deposits clearly. Usually, copper wires display dark or multicolored surfaces, and their discoloration can vary greatly along the entire length of the conductor. Until recently, costly laboratory tests were the only reliable method for detecting corrosive sulfur in transformer oil.

Sulfur exists in transformer oil in different forms and various compounds. Copper sulfides can appear with very diverse characteristics. Because of this, technicians suspect that undetected copper sulfides likely cause numerous malfunctions in transformers and reactors. The portable CS100 Kit offers a rapid, convenient, and affordable testing option.

Common copper corrosion tests refer to established procedures, such as ASTM D1275 Method B and IEC 62535 (the CCD test).

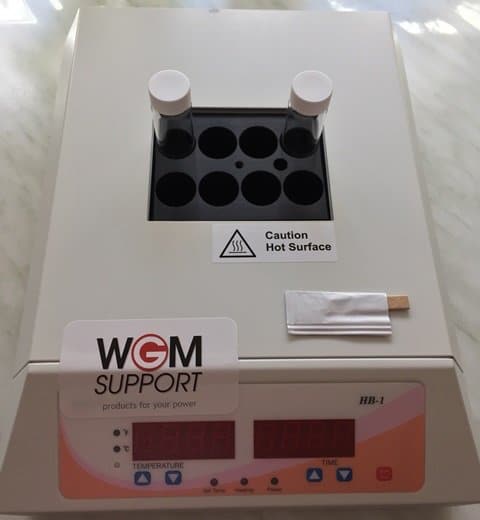

The IEC 62535 procedure, known as the CCD test and formerly named Cigre A2.32.TF01, tests copper conductors by accelerated oxidation at high temperatures. During this process, technicians wrap copper conductors in kraft paper and then perform a visual inspection. This step aims to identify corrosive sulfur compounds, which could contaminate the cellulose insulation with copper sulphide.

The ASTM D1275 Method B also uses accelerated oxidation, but on an electrolytic copper strip at 150°C for 48 hours. Afterward, a visual assessment checks for sulfur compounds that might contaminate copper surfaces. This method provides additional insights, allowing for a more comprehensive understanding of copper contamination risks.

We offer you advice on the following topics: Corrosive sulphur | Insulating Oil | Transformer oil