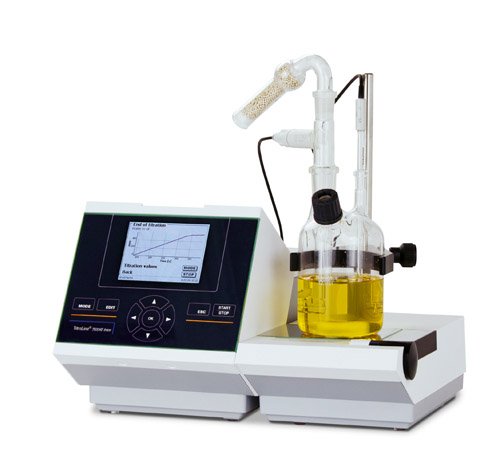

Karl Fischer Water Content Determination | KF-750

Karl Fischer Titration KF-750 | Determination of the water content: Karl Fischer Titration has its place in every laboratory. Karl Fischer Titration KF-750 The KF-750 is a coulometric titrator. The water content and the water content determination according to Karl Fischer Titration impresses with its very good accuracy. With this KF titrator, nothing can actually go wrong when determining the water content according to Karl Fischer. The display, which is large and easy to read, shows every step in the process in a dialog. The pre-parameterized methods thus additionally facilitate the work. In addition, the versatility of the two KF titrators makes the instruments efficient and easy to operate. The KF measuring station is suitable for almost all areas such as the pharmaceutical, chemical, food or petroleum industries.

The coulometric KF titrator is the ideal instrument for determining even the lowest water content in samples. In the coulometry of a titration solution, the determination of the concentration titer is not necessary, making it easier to operate than in volumetric titration. Many experienced analysts still feel the smell of pyridine in their nose with horror when they hear the name Karl Fischer. However, modern reagents and easy-to-operate analytical instruments cleaned up thoroughly with such ideas. Today, coulometric and volumetric Karl Fischer titrators allow practically all applications to be performed simply, quickly and accurately. Because of its selectivity and accuracy, Karl Fischer titration has become the most important method for water and moisture determination. With the KF-750, titration can also be followed “live” in the form of a measurement curve. At the touch of a button, it is possible to switch between classic and graphical display.

We offer you advice on the topics of: Determination of water content | Karl Fischer Titration | Karl Fischer Method