Understanding the Importance of Battery Testing

Research on battery testing shows that a battery cell’s internal resistance gradually increases with both age and discharge history. Since batteries are frequently used as backup systems in power supply, especially in UPS systems, their operational readiness becomes crucial in the event of a power outage. Therefore, it’s essential that the battery consistently delivers the required capacity to support such systems effectively.

Moreover, regulations mandate regular battery testing, particularly for safety-critical systems backed by emergency power sources. According to VDE standards, these tests must always be documented and thus remain verifiable at any time.

The Necessity of Regular Battery Testing

As a result, regular battery tests are mandatory. These tests assess the battery’s storage capacity and performance under load over a specific period. Notably, these tests are conducted in the batteries’ current operational state, as outlined in DIN EN 60896-11. This ensures that the assessment reflects the battery’s actual performance conditions.

The Role of WGM Support in Battery Diagnostics

Battery testers from WGM Support offer both partial AC resistance measurement and DC terminal voltage assessment of secondary batteries online. This provides reliable data on the battery’s condition without reducing the remaining battery capacity during testing. Consequently, users receive a clear and accurate battery diagnosis. Additionally, these battery tests are compatible with any battery system. By using our battery tests, which are fully compliant with current standards, you can ensure that your products consistently meet the highest quality requirements.

Battery Analyzer | BTA 100 | Battery Diagnosis

The Battery Analyzer BTA 100 is ideal for maintenance, troubleshooting and testing the characteristics of individual stationary batteries. It helps you to eliminate weak batteries to ensure the performance of your battery systems. Battery diagnostics will detect errors and can be managed in the battery management system. The BTA 100 is a very effective and economical battery testing device. The BTA 100 tests the internal battery resistance or conductivity as well as the voltage of the battery.

Testing the battery helps to identify weak cells before they cause problems. For telecommunication networks, data centers and electricity utilities the management and testing of batteries is a very important task to maintain power integrity. This BTA 100 is widely used by service providers, operation and maintenance teams for battery management and measurement. The lifetime of a forklift battery in the form of a lead-acid battery depends on its care. However, this is only true under optimal conditions. Incorrect charging, overuse and lack of maintenance and care can strongly shorten the service life.

It is not important whether you check closed (VRLA) or vented (VLA) lead-acid batteries or NiCd cells. WGM Support has the right equipment for your battery maintenance. The products and related accessories provide useful battery health data without generating significant overheads or a possible reduction in remaining battery power. The Battery Analyzer BTA 100 is a portable test instrument. BAT 100 are the ideal test tool for maintaining.

We offer you advice on the topics of: BTA 100 Analyzer | Battery Internal Resistance | Stationary lead-acid battery

Battery Condition Analyzer | BTA 200 | Stationary Batteries

Introduction to the BTA 200 Battery Condition Analyzer

The BTA 200 Battery Condition Analyzer is an advanced device specifically designed for the precise monitoring of battery health. Stationary batteries, especially those used in critical applications such as emergency power supply systems, benefit greatly from this device. The BTA 200 combines modern technologies to ensure that batteries function optimally.

Measuring Internal Resistance

One of the key functions of the BTA 200 is the measurement of internal resistance in batteries. This measurement is crucial as it assesses the condition of the battery electrodes and the stability of the cell structure. In emergency power systems, where a stable energy supply is essential, internal resistance measurement plays a central role. It helps to detect potential issues early, allowing for corrective measures before failures occur.

Conductivity Testing for Improved Efficiency

In addition to internal resistance measurement, the BTA 200 can also test the conductivity of the battery. This function enables the evaluation of the battery’s electrical performance. A good conductivity rating ensures that the battery operates efficiently and provides a reliable energy supply. This is particularly important since consistent performance is critical for the efficiency of energy systems that rely on stationary batteries.

Connection Cable Testing for Secure Connections

Another important feature of the BTA 200 is its connection cable testing. The device checks whether the battery’s cable connections are functioning correctly. Poor connections can lead to voltage drops and disrupt energy transfer. Such issues could result in significant failures in critical applications. The BTA 200 ensures that the connection cables do not cause power losses, improving the overall reliability.

AC Signal Discharge for More Accurate Measurements

Using the advanced method of AC signal discharge, the BTA 200 can measure the battery’s internal resistance even more accurately. This method allows for the assessment of resistance under varying operational conditions. As a result, more precise measurements are obtained, particularly for batteries subjected to different loads.

User-Friendly Operation

Another outstanding feature of the BTA 200 is its user-friendly interface. The device is equipped with a TFT touchscreen as well as a keypad, making it easier to operate. Thanks to this intuitive interface, it is simple to navigate the various functions and perform tests. This greatly facilitates monitoring and testing, for instance, in centralized battery systems.

Data Management and Analysis for Informed Decisions

Finally, the BTA 200 offers comprehensive data management and analysis capabilities. Specialized software enables efficient management of all collected data. These can be analyzed and reports can be generated to support informed decisions in battery management. This helps to optimize the performance of battery systems and enhance their reliability.

Conclusion

In summary, the BTA 200 Battery Condition Analyzer is a versatile and powerful device. It offers a range of features specifically tailored for the analysis and monitoring of stationary batteries. With its precise measurements, user-friendly interface, and efficient data analysis, the BTA 200 is an essential tool for battery management in critical systems such as emergency power supply, telecommunications networks, and data centers.

We offer you advice on the topics of: Stationary Batteries | Battery Analyzer | Battery Diagnostics

DC Ground Fault | GFL1515 | Battery Ground Fault

GFL1515: Essential for Detecting DC Ground Faults in DC Systems

The GFL1515 is an essential measuring device for detecting DC ground faults in various DC systems. This GFL1515 Detector is crucial for identifying faulty grounding, especially where electrical cables are damaged or show leakage to the ground.

Fault Detection Through Signal Injection

The GFL1515 detects unintentional DC ground faults by injecting a low-frequency signal into the faulted polarity. Using current clamps and a portable receiver, operators can follow this signal to pinpoint the physical location of the DC ground fault.

Online Measurements with High Voltage Tolerance

The GFL1515 enables measurements even in online DC systems. While the device’s output current remains low, its output voltage can reach up to 1000V, allowing it to function safely without interference. Per the NERC PRC 002-6 standard, the battery and DC power system must be checked for unintentional grounding every four months. If a ground fault is found, the GFL1515 allows for precise fault localization without disconnecting the live circuit.

Method for Fault Localization

The GFL1515 uses several methods to locate faults accurately, based on these principles:

Signal Generator and Return Circuit

The signal generator connects to the DC system with two test leads, injecting a low-frequency current signal. This signal flows through the circuit, exits at the faulted grounding point, and finally returns to the generator. This return circuit assists in signal tracing in the next step.

Signal Receiver for Directional Tracking

The signal receiver tracks the signal’s direction, which always points toward the fault. Using one clamp on two busbars, or two clamps on separate busbars, the device works efficiently with strong anti-interference capability, even in online systems.

Signal Strength and Phase Angle Changes

The strength and phase angle of the signal change significantly before and after the grounding fault. These changes help pinpoint the exact fault location with accuracy.

We are happy to provide further guidance on the topics: Battery Ground Fault | Ground Fault DC | DC Ground Fault.

DC Load Bank | Battery Test | Battery Capacity

DC Load bank Solutions – We offer DC loadbanks for various industries, along with custom models designed for high performance. Our loadbanks simplify DC load testing and battery capacity measurement, making these processes quick and reliable. With a wide range of models, we cover voltages from 12V to 480V and handle currents up to 600A. As a result, our loadbanks are widely used in fields like telecommunications, power supply, data centers, and forklift operations. They are also critical for uninterruptible power supplies (UPS), central battery systems (CBS), and emergency power systems (EPS).

Our DC loadbanks are known for their unique design and high reliability. They support precise testing of DC loads, battery capacity checks, and detailed diagnostics. With optional software, each cell’s discharge values can be monitored in real-time on both the load bank display and a connected PC. Regular battery capacity checks are essential for reliable maintenance. Our loadbanks are trusted energy sources for power systems and other essential operations, including emergency lighting.

Load testing is essential to confirm that stationary batteries meet required standards. These tests provide clear insights into a battery’s condition, aiding accurate diagnostics. Key indicators, like battery capacity, state of charge, and discharge rate, reveal crucial details about battery health. In critical environments like data centers, airports, or hospitals, a discharged or failed battery could have severe consequences. To prevent such risks, WGM Support offers a range of custom battery loadbanks, specifically for constant current discharge tests and battery capacity evaluations.

Expert Support – Our team is available to advise on battery testing, measurement, and capacity checks. We ensure you have the right tools and information to keep your systems running reliably.

We are happy to advise you on topics like: Loadbank | Battery measurement | Battery capacity testing

Forklift Battery | BLE 600 | Batteries

BLE 600: A Versatile Battery Management Device

The BLE 600 is a compact 3-in-1 device designed for charging, discharging, and activating lead acid or nickel-cadmium (NC) batteries. It is ideal for forklift batteries and battery charging systems used in uninterruptible power supplies (UPS), emergency lighting systems, and central battery systems. Thanks to its small size, the BLE 600 is a portable and convenient tool for regular maintenance of single cells, especially older ones, with voltages of 1.2V, 2V, 4V, 6V, 8V, and 12V.

Flexible Functionality for Battery Maintenance

The BLE 600 can perform its three functions—charging, discharging, and activating—either separately or simultaneously. This flexibility enables users to effectively maintain forklift batteries while streamlining overall service. When used together, the charging and discharging functions can charge and discharge the batteries in one or multiple circuits using a low constant current. The device can even perform these operations multiple times individually.

Regeneration and Monitoring Capabilities

The activation function repairs damaged material on the battery electrode plate, correcting any malfunctions and thereby regenerating the battery. This process increases the capacity of the forklift battery. Additionally, as a battery load simulator, the BLE 600 checks the battery’s discharge status and can conduct capacity tests to accurately determine the actual capacity of the battery systems.

By regenerating forklift batteries, the BLE 600 enhances their efficiency and optimizes resource usage. It also allows for long-term monitoring of battery conditions, continuously checking the traction battery to prevent serious damage over time. The device features a user-friendly interface with both touchscreen and keyboard controls. Furthermore, it includes a direct USB drive for easy data transfer to a PC. Software updates can be completed quickly, and users can download reports in Excel format at any time.

We offer you advice on the following topics: Stationary batteries | Battery | Battery charging / discharging.

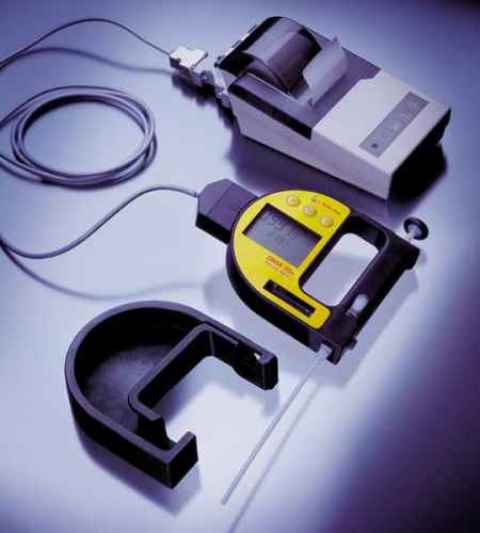

Density Meter | Digital Hydrometer

The portable density meter is ideal for beginners. It measures sample density directly and easily on-site. Using the built-in pump, the device draws samples from the storage container and instantly displays the results—either as density or as concentration in units like °Brix, %v/v alcohol, or %w/w H₂SO₄ (sulfuric acid). Thanks to its lightweight and compact design, the measuring device is also suitable for hard-to-reach samples, such as batteries in tight shelves or wine samples from stacked barrels.

Technical Highlights of the Density Meter Compared to the Glass Hydrometer

- Minimal Sample Volume: Only 2 ml of sample is needed, helping to avoid sample waste.

- Direct Sample Collection On-Site: The built-in pump draws samples directly from the container, simplifying the process.

- Integrated Conversion Table: Results are displayed directly in preferred units, eliminating the need for extra calculations.

- Wide Measurement Range: This device can replace a full set of hydrometers.

- Automatic Temperature Compensation: Results are precise and reliable within seconds.

- Efficient Data Management and Easy Transfer: Stored results can be automatically transferred, eliminating manual note-taking.

- Consistent Results: The results are reliable and consistent, regardless of user experience.

- Lightweight and Robust Design: This allows for easy transport and safe storage.

This device is the lightest of its kind on the market. Its slim design allows it to fit into narrow spaces, such as wine cellars or battery production facilities. A protective case, rubber housing, and shoulder strap make the device ideal for safe on-site use. It is leakproof (IP54) and reliably resists sample splashes. The chemical resistance of sample-contacting parts has been thoroughly tested, protecting the device from the effects of solutions and acids for a long-lasting lifespan.

Smart Features for an Optimized Workflow

The device includes a backlit display and an illuminated measuring cell, making it easy to use even in dark environments. Sample IDs can be saved and assigned to sampling locations. Stored results can be conveniently printed or exported via the IrDA interface, enabling quick and efficient data processing.

We are happy to advise you on topics related to: Lead Batteries | Battery cells | Battery testing

Battery Impedance Tester | Battery Test | BITE 3

The Megger BITE 3 battery impedance tester measures key parameters for assessing the condition of lead-acid batteries with a capacity of up to 2,000 amp-hours. The measured values include cell impedance, cell voltage, and cell junction resistance. Additionally, the BITE 3 performs an internal ohmic test.

For the first time in a device of this kind, the BITE 3 also measures trickle charge current and superimposed AC current. An integrated spectrum analyzer displays the harmonic content of the AC current. The device’s firmware is internet-capable and can be updated; it also supports multiple languages.

The BITE 3 is particularly user-friendly, making it ideal for the regular inspection of lead-acid batteries. It measures internal impedance, junction resistance, cell voltage, as well as trickle charge current and ripple current. These values, together with temperature, specific gravity, and other battery parameters, enable a comprehensive assessment of battery condition—from terminal to terminal—and, to some extent, of the charger (specifically, the superimposed AC current and its harmonic components).

Megger recommends incorporating the BITE 3 as part of a comprehensive battery maintenance program:

- For lead-acid batteries, a semi-annual inspection is advisable,

- For VRLA batteries, a quarterly check is recommended.

Overall, the BITE 3 is among the easiest and most reliable devices for monitoring batteries and chargers.

We will be happy to advise you on the subject: Battery measurement | Battery testing | Battery capacity test.